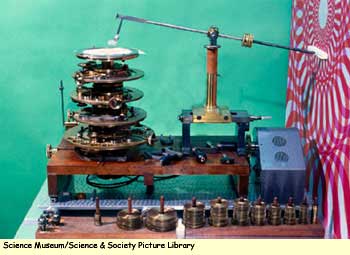

This Hartley/Plant 2-part chuck was made to the design published in English Mechanics, October 1910.

Geometric chucks were, and still are, used with an ornamental lathe for cutting of a variety of cyclic designs.

This was built for the fun of it, a fairly simple program controlling a CNC engraver could produce the same effects with considerably less effort !

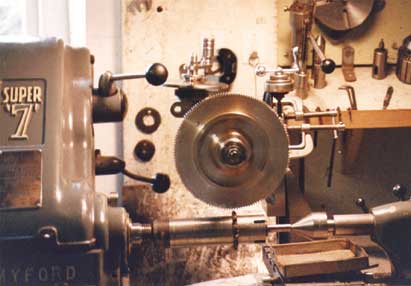

Machinery used: Myford S7, Boley milling machine, Shaper said to have come from a 1st World War battleship ! & Pillar drill

An interesting project but a considerable time waster, with over 2 million possible designs there is a tendency to keep making slight adjustments to the gear trains and/or slides to see what kind of pattern will be generated. However, that is nothing compared to the time wasting that could be accomplished with the 4-part & 7-part chucks shewn below

| Home | Back to Projects | Links |