On telling of my acquisition to an old friend, a retired RN engineer officer, he thought for a moment and replied ‘Was that wise ?”. Other derogatory comments included the idea that if the Soviets came to blows with NATO, their idea was to throw these bikes at our troops !. Anyone who has come across these machines will understand the comment, they are built like the proverbial brick outhouse.

I subsequently found the dynamo was in fact an alternator which when tested by the guys at Tytherley Vehicle Electrics at Chard was found to be as dead as that parrot. I also discovered, somewhat late in the day, that spare alternators for 1974 Russian motorcycles are rarer than rocking horse droppings.

The guys at Chard suggested I fit a car alternator and they gave the price for various models ranging from a Bosch at £35 up to a Nippon Denso at £135.

A quick measurement of the original alternator showed that the Nippon Denso was perfect but also that the Bosch would JUST fit. Guess which I went for ? yes the Bosch ! It is a Bosch ACR (several manufacturers make ACR type alts. & they are often fitted as an upgrade from a dynamo on older cars)

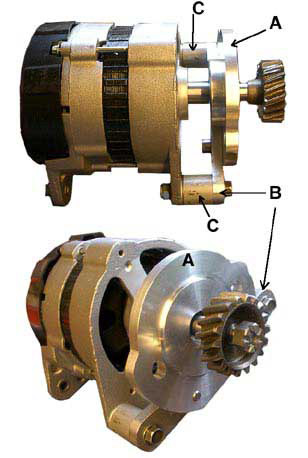

Key to picture:

A – adapter plate with bearing to support the rotor spindle extension

B – bridging piece (I would have preferred to make this & the adapter plate in one piece but did not have the material to hand)

C – spacers, these only need to be long enough to allow the nuts to be put on the engine case studs.

The is no coupling between the rotor spindle & the extension, simply a support bearing in the adapter plate.

The only critical dimension is from the adapter bolting face to the gear, this was taken from the original alternator. The adapter plate has elongated mounting holes to give a little adjustment for meshing the gear, this can only be done by ‘feel’ on the shaft once all is assembled. I must have it about right as it runs quiet (at least as quiet as the original !). Although the alternator as fitted feels quite rigid, it is only held together with 3 x 6mm bolts so I intend to put a support bracket from the end case to the frame at the tank bolt. (Having said that, when a sparkplug jockey fits one of these to a car he hauls of with a 2 foot tyre lever to tension the belt so they can’t be that fragile !)

This was all a bit ‘trial & error’, the size of this alternator does not give much in the way of spare room, if I had to do it again I would save my pennies & buy a Nippon Denso, make a pattern and have the adapter plate, spacers etc. cast as one piece.

Material cost to me was just for the alternator, the rest was from the workshop, I do not intend to work out my labour costs !!!

Final Note: Just got the alternator working fine when the bike lost compression on one side so sat in the garage waiting in line with the other bikes that required surgery.

Ah ! Don’t you just love the old stuff.